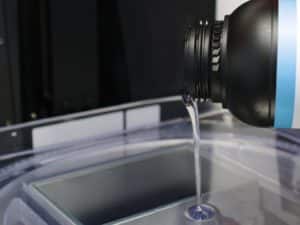

PRO2 3D Printer

Specifically designed for Audiology

(Headquarters in Sydney, Australia)

High Volume Digital Production

The Asiga PRO2 3D Printer platform size offers the capacity to produce up to 20–35 ear molds during each print job. Depending on the height and the material, the print job is completed in approximately 1 hour or so.

The PRO2 offers a large build platform speed and reliability capable of producing thousands of ear molds per year.

Image Courtesy of Asiga

Key Features

1) Intelligent Slide and Separate™ Technology (iSAS™)- minimal supports, maximum speed

2) Open Material System- use any suitable 3rd party material

Example: 3D printed ear mold for a hearing aid.

Image courtesy of Asiga

For more info visit https://www.asiga.com/

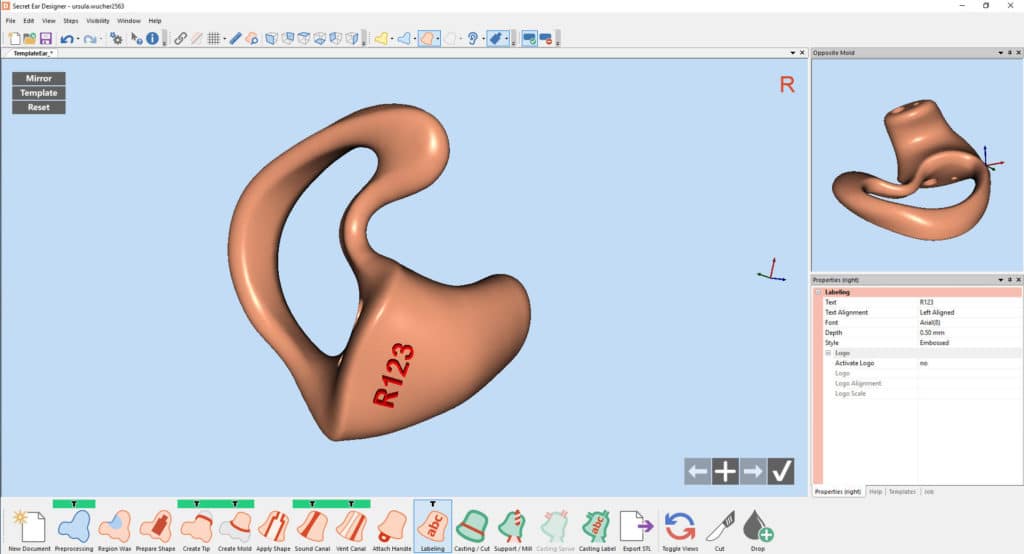

Secret Ear Designer Software

(Headquarters in Switzerland)

Image courtesy of Cyfex Software.

Digital manufacturing has arrived in the hearing aid industry. The use of CAD/CAM technology, which to date has only been used in industrial manufacturing is now also beneficial for laboratories. The 3D digital modeling allows us to customize the fit exactly.

Benefits

Low costs

Reduced need for training

Ultrafast design process

World-Class Customer Service

For more info visit https://www.cyfex.com/en/hearing

Detax

DETAX is one of the worldwide leading manufacturers of high quality medical products. For more than 65 years, DETAX have been developing biocompatible silicones, light curing resins and high performance 3D composites for medial applications. As medical device manufacturer, DETAX is certified according to the latest standards for medical devices. DETAX products are exported to over 100 countries around the world.

Biocompatible 3D Printing Material

(Headquarters in Germany)

LUXAprint MOULD

500 g- Production of ear molds

LUXAprint SHELL

500 g- Production of ITE shells

LUXAprint CAST

1000 g- Production of silicon cast forms

For more info visit https://www.detax.de/en/shop/audio