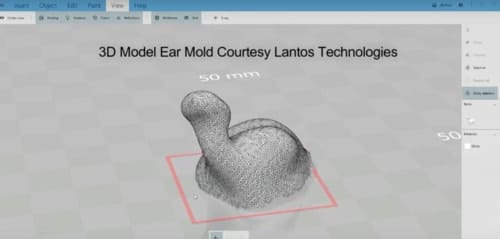

Images Courtesy of Lantos Technologies

Scan

The 3D Ear Scanner digitally maps the topography of the client’s ear all the way down to your eardrum.

Digital Mapping

The scanner collects over 1,000,000 data points, creating a 3D image of the unique geometry of the client’s ear. To make sure we get a perfectly tailored and comfortable fit.

A disposable membrane is inflated to conform to the client’s unique anatomy and a 3D digital model is built in real time using the digital data points collected.

Summary of Steps:

1) Scan the ear directly, using the Lantos 3D Ear Scanner.

2) Design the digital model using Cyfex Software to prepare the stl file for 3D Printing.

3) 3D print the ear mold, using Asiga PRO2.

4) Finish the post 3D printing process

(Picture above)

Jason Szolomayer completed some training with Dr. Brian Fligor, using the new 3D ear scanner. Jason traveled to the Lantos Technologies office in Boston, during the fall of 2018.

For more info read our blog about Jason’s visit to Lantos Technologies HQ for training.

https://3dp4me.org/dr-brian-fligor/